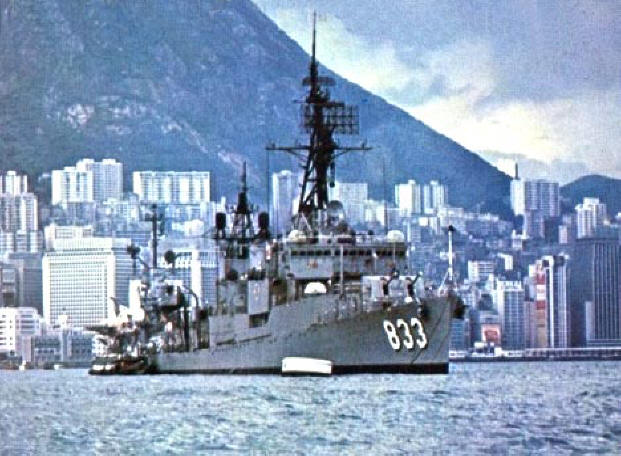

USS Herbert J Thomas in Hong Kong Harbor circa July 1969. There's

an aircraft carrier anchored behind us making the Thomas appear to

have 3 mast. The ship was built in 1945 in Bath, Maine. I served aboard

from October 68 to October 70. The ship was decommissioned in December

1970 and placed in the inactive fleet reserve until 1974 when it was

transferred to the Republic of China where is served another 25 years.

In 1999 it was sunk as an artificial reef off the coast of Taiwan.

Having built a number of reefers for Tom Miller's layout in Portland,

Oregon, I was invited to attend a VIP tour before he had his open house

for the narrow gauge convention. Tom has an impressive collection of

custom built model ships which planted the idea of making the destroyer

I was on in the late 60's. The Thomas was a gearing class destroyer.

There were 99 gearings built between 1944 and 1946. Most had minor

upgrades, namely to the radar systems in the 1950's. In the 1960's 98 of

the gearings went through a FRAM upgrade. FRAM meaning Fleet

Rehabilitation and Modernization. There was a FRAM 1 and a FRAM 2

modification. The Thomas received the FRAM 1 starting in 1964 at Mare

Island, California. The overhaul was completed in 1966. The FRAM

upgrades were to remove the old WW II weapons and replace them with

"modern" anti submarine warfare weapon systems and "state of the art"

radar systems. The ships were striped down to the main decks and all

superstructures rebuild. This time in aluminum to keep the weight down

for all the new weapons.

The Thomas was selected to receive a one of a kind FRAM re-build. It

received what was called a STOPS system. STOPS stands for Shipboard

Toxicology Operational Protective System. The hull was pressurized with

revolving doors fore and aft and double hatch pressure doors along the

port and starboard sides and no portholes at all. If you look at the

picture, you can see glass bubbles on either side of the bridge. All

other destroyers, gearing or another class, have open bridge wings for

the lookouts. On the Thomas, the bridge was wider and closed for the

pressure system. Hence the bubbles for the lookouts. The ship had

several other changes made to the superstructure, mostly to accommodate

the STOPS build out. You can Google the ship and read about it. You will

see many sites that talk about Project Shad. Rather a sad story of what

the government did to our young men while serving their country. I won't

get into that here. I'll leave you to read about it and form your own

opinions. I made contact with Carl Ellis who served aboard a couple

years before I did. He was aboard when the ship was involved with Shad.

A couple of his friends have died from complications of those events.

Carl also built a model of the Thomas and the two of us have been

"comparing" notes of our time in the navy.

So, enough of the boring stuff, lets get going..................

Quality model ships, like our quality model trains are expensive. I did

a lot of searching and found an affordable kit manufacturer in AZ. The

company is BAD Ship Models. They have kits of the Gearing Class

Destroyers in WW II as built and post FRAM 1 modification. So in the

spring of 2012, I purchased the FRAM kit and was on my way. When I

received the kit, I found that many of the detail castings and other

parts to be a bit rudimentary for my taste. Started searching the net

and found a couple high end parts manufacturers. Namely John R Haynes,

Tom's Model Works and Scale Shipyard. Every month I sent off an order to

one of the manufactures buying replacement parts. I ended up having more

dollars in parts than the original kit. Many of the parts I had to make

as the Thomas was a one of the kind and no one was going to make parts

that only one destroyer in the whole fleet had aboard it.

I started construction of the hull in November 2013. BAD models are a

plank on frame type of construction. The kit came with a keel and 7

frames. Well, that wasn't enough frames for a guy that builds "rugged"

1:20 scale rolling stock. I added another 14 frames to the keel. To save

room on the page, I am making the pictures a thumbnail that you can

click to enlarge and then press your back button to return.

I made a frame first. Then rubber banded the sub deck to it. The frames

are glued to the sub deck after that and the balsa planks glued on. For

whatever reason, I didn't take any pictures of that process. Trust me,

it took quite a while to attached a couple hundred 1/8" by 3/8" balsa

sticks. Once they were all on, I filled all the gaps with wood putty and

sanded smooth. Then added 8 to 10 coats of fiberglass resin until

I had a thickness of about 1/8". Then I painted the hull to specs. I

added about 5 lbs of #5 lead shot between the frames for ballast.

It will never see the water but I didn't want it to be top heavy.

Above are pictures of the propeller guards and the running gear. The

running gear came with the kit but the prop guards that came with it

were vacuum formed to be reinforced with wood dowel. Wasn't going to cut

it with me.

When I get to pictures of the superstructure, there'll be guns, radar

and other pieces that you'll think got magically built or they came

pre-built. So, here are pieces I made or castings from John R Haynes

that I super detailed.

This is a T-Mark 6 Fanfare device. It was used as a noise maker that was

towed behind the ship if a noise seeking torpedo was fired at the ship.

The trailing devices had noise generators inside that would, hopefully,

draw away a noise seeking fish. Most of that type of torpedo was

discontinued by our enemies after WW II. Every non US or UK sub we

encountered was Soviet and pretty sure carried active sonar searching

torpedo's. Glad we never had to test this thing!!

I couldn't use any of the superstructure material as the kit is based on

the USS Joseph P Kennedy DD-850. Also a gearing but very different from

the HJT (Herbert J Thomas). I use 1/8 poplar plywood for all bulkheads

and skinned it with .010" styrene. Squadron Green puttied the joints,

sanded and painted. The stanchions are 1/16" brass rod with etched brass

stanchions solder to them. The little eyes will support the three

stanchion cables of the main deck.

More main deck structure. The bridge is starting to come together as is

the rear structure. The orange colored castings came with the kit. Some

will get used, some not.

Forward funnel and ASROC launcher. ASROC stands for Anti

Submarine Rocket. We could fire a MK 44 torpedo or a nuclear

depth charge out a couple miles. Remember the saying, close only

counts in horseshoes and hand grenades? We added horseshoes,

hand grenades and nuclear depth charges. Also added is the

bridge roof with bubbles.

Bow detail. Most of this detail is from John R Haynes. Some of

the bulkhead detail I made.

Forward view. Torpedo deck view. The plumbing under the bridge is

the forward re-fueling stations. One on each side under the bridge.

This was so we could take on fuel from either side of the ship while

underway. More times than not, we took on fuel from the port side.

Probably just the luck of the draw as we were fitted for both sides.

Also pictures of the bridge roof and the start of the main mast.

More pictures of the mast. The SPS 10 radar (upper antenna) and

SPS 29 radar (lower antenna).

This is the rear mast or ECM mast. ECM standing for Electronic

Counter Measures. I was a sonar technician, not a radio tech so I'm

not 100% sure what all the various antenna's were for. I know some

of the UHF antenna's were for the IFF or Identification, Friend or

Foe. This antenna was 100% scratch built. I sure know why I went to

1:20 scale trains. This is 1:96 scale or smaller than HO scale.

After I built the aft mast, I decided to go back to the bow and

start the final work completing the model from the bow to the stern.

I used etched brass stanchions from John R Haynes. The stanchions are

available in 1, 2 or 3 rail. 3 rail was used on all the main deck. I

used .025" wire for the top rail and .020" wire for the second and

third (bottom) rails. Once placed a micro touch of solder held all

in place. Then they got painted. White on the top rail and gray on

the stanchions, second and third rails.

Finished look of the bow

At this point I made contact with the Shapeways designer that made

the MK 32 torpedo tubes. I asked him if he could design more items

for my model which he readily agreed to do. Mark lives in the UK and

severed in the Royal Navy so hardware on the two navy's vary quite a

bit. First up I used his refueling funnels on the torpedo deck

verses mine. I also had him make up the DASH helicopters, The ASROC

launcher, loader and shipping containers. Fire nozzles and

boatswains highline chair. Binoculars and loudspeakers.

Above is the finished bridge top. The finished CIC roof with the 3D

printed MK 37 fire control direct and binoculars. The signal lights

and some other parts are white metal John R Haynes parts. The rest

are scratch built. The last 3 are of the ASROC deck. The ASROC launcher is the brown resin

casting. This was the one supplied with the BAD kit. Not a terrific

casting. I did replace it with a Scale Shipyard casting and then

again with a 3D Shapeways unit. The forward and aft funnels are set

in place as is the ASROC control booth.

Here is the ASROC loading crane with ASROC torpedo and the Scale

Shipyard ASROC launcher. During loading operations, I was the crane

operator. In the first picture, the white casting is the crane's rail locker

to keep it out of the weather as many of the moving parts were not

painted and would would rust or corrode with salt spray hitting it.

First picture is of the new Shapeways 3D ASROC launcher and loading

crane with missile. Second is the ASROC magazine. Third is of the

top of the ASROC magazine and DASH hanger, forward side. Last is the

Shapeways boatswain chair atop the DASH hanger.

I made the life nets on the helo deck so they could be up or down.

Second picture is with the nets down followed by nets up. Beings the

hull was sealed and under +1 to +2 atmospheric pressures, extra

power to run the air conditioning and purification equipment was

needed. All other Gearing class destroyers used only a large diesel

engine for the electrical generation. On the Thomas, we had a gas

turbine turning our generators. Think of it as a jet engine as it's

fuel was avgas or aviation gas. The last two pictures show the

intake and exhaust stack for the gas turbine.

First up is the final finish of the stern, the life boat / motor

whaleboat, the starboard boom and the Shapeways 3D DASH helicopter

assembled and painted. The only shots not pictured so far is the

bulkhead detail along the main deck. That deck consist of the two

wells, one on the port and one starboard, both just aft of the

torpedo deck. Then the long port main deck leading back to the stern

and the starboard deck again leading from ASROC deck to the stern.

First is the starboard well, then the port well. Next two are the

port side to stern and last, starboard side to stern.

Click the Finished button at the top of the page for a series

of pictures of the finished model. This was a one year project. Lots

of research and pouring over old photo's and cruise books to do the

model right.

On to the next project!!!